Aircraft Hydraulic Systems Air Force - Hydraulic systems work on the principle that fluid, unlike air, is virtually incompressible. This makes it a good medium to transmit and multiply forces. Incompressibility is not the only requirement for a useful hydraulic fluid; Viscosity, stability, and the tendency to resist vaporization are important too.

Pumps can be classified as either positive displacement or non-positive displacement. A positive displacement pump is the most common type used in hydraulic applications and works by trapping a fixed amount of fluid at the pump inlet and forcing (displacing) that trapped volume into the discharge pipe at the outlet.

Aircraft Hydraulic Systems Air Force

Chemical stability refers to the fluid’s ability to resist oxidation and deterioration during a typical operational lifespan. It is important that the fluid is able to operate as designed during periods of high temperature where deterioration of the fluid is accelerated.

Fluid Properties

The purpose of an actuator is to convert fluid pressure into a mechanical force that can be used to perform useful work. Work is the product of force and displacement and so applying a pressure to one side of an actuator will cause that actuator to move with a force equal to the pressure difference multiplied by the actuator's cross-sectional area, and perform work such that energy in the system is conserved.

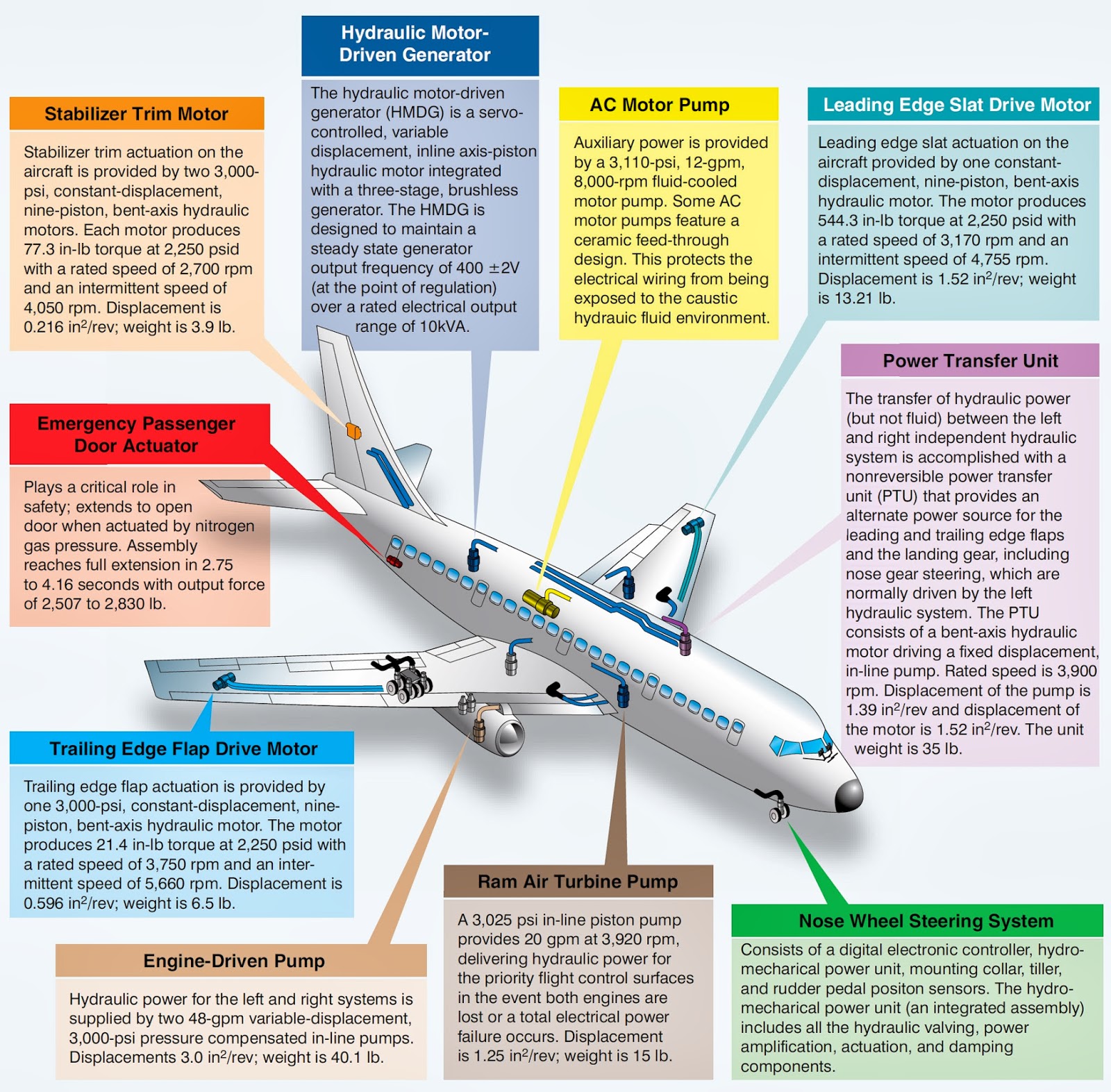

An aircraft hydraulic system allows for forces to be applied, multiplied, and transmitted from one location to another through an incompressible fluid medium. Hydraulics are a critical system on almost all modern aircraft. Light aircraft primarily make use of hydraulics to augment and transmit braking forces from the cockpit to the brake disk or drum.

Larger, more complex aircraft may use hydraulics to actuate landing gear, flaps and control surfaces in addition to braking and nose-wheel steering. An announcement by the Captain of a fully-boarded Boeing 757-200 about to depart which was intended to initiate a Precautionary Rapid Disembarkation due to smoke from a hydraulic leak was confusing and a partial emergency evacuation followed.

The Investigation found that Cabin Crew only knew of this via the announcement and noted subsequent replacement of the applicable procedures by an improved version, although this was still considered to lack resilience in one respect.

Chemical Stability

The event was considered to have illustrated the importance of having cabin crew close to doors when passengers are on board aircraft on the ground. Redundancy should always be built into the hydraulic system to ensure that failure of a single component does not result in failure of the whole system.

The primary hydraulic pump is a critical component and as such there is usually an emergency pump installed downstream of the reservoir to operate if the main pump fails. The emergency pump is usually electric powered and runs off the aircraft’s electrical system.

A check valve operates as a one-way valve, allowing fluid to flow unimpeded in one direction but not in the other. A common check valve uses a spring-loaded ball seated inside a housing. The spring compresses under pressure to allow flow in the desired direction.

Once the flow stops (or reduces below a set rate), the ball seats in the housing, cutting off the flow. A variable volume pump will deliver a volume of fluid proportional to the demands of the particular system.

Variable Displacement

A compensator built into the pump automatically regulates the pump output based on the system pressure. A gear pump with a pressure cut-off valve acts in the same way. On 26 February 2013, the crew of a Boeing 752 temporarily lost full control of their aircraft on a night auto-ILS approach at Keflavik when an un-commanded roll occurred during flap deployment after an earlier partial loss of normal hydraulic system pressure.

The origin of the upset was found to have been a latent fatigue failure of a roll spoiler component, the effect of which had only become significant in the absence of normal hydraulic pressure and had been initially masked by autopilot authority until this was exceeded during flap deployment .

A closed center system places the actuators in parallel to one another. This requires that the pump output be controlled to accommodate a differing number of actuators operating simultaneously. The arrangement is such that the system is always under pressure which results in a quicker response when an actuator is activated.

On 4 October 2014, the fracture of a hydraulic hose during an A330-200 pushback at night at Karachi was followed by dense fumes in the form of hydraulic fluid mist filling the aircraft cabin and flight deck.

Closed Center Systems

After some delay, during which a delay in isolating the APU air bleed exacerbated the ingress of fumes, the aircraft was towed back onto stand and an emergency evacuation completed. During the return to stand, a PBE unit malfunctioned and caught fire when one of the cabin crew attempted to use it which prevented use of the exit adjacent to it for evacuation.

It is important to reduce swirling and surging of the hydraulic fluid in the reservoir as far as possible. Baffles and fins are usually incorporated to reduce the motion of the fluid during flight, and to keep the formation of bubbles to a minimum.

Larger aircraft make use of a primary engine-driven hydraulic pump alongside an auxiliary electric pump in the event that the primary pump fails. Typically the hydraulic systems in these aircraft drive not only the braking system but also flaps and landing gear retraction systems.

A thermal relief valve is designed to relieve excess pressure in the system due to thermal expansion of the fluid. These valves are usually smaller than system relief valves and used where a flow control valve prevents pressure from being relieved due to the one-way nature of the valve.

Principles Of Hydraulic Operation

On 1 November 2011, a Boeing 767-300 landed at Warsaw with its landing gear retracted after declaring an emergency in anticipation of the possible consequences which in this event included an engine fire and a full but successful emergency evacuation.

The Investigation attributed inability to achieve successful gear extension using either alternate system or free fall to crew failure to notice that the Battery Busbar CB which controlled power to the uplock release mechanism was tripped.

Gear extension using the normal system had been precluded in advance by a partial hydraulic system failure soon after takeoff from New York. In the event of a System Overheat or Loss of Pressure, following the Quick Reference Handbook (QRH) or ECAM checklists may result in recovery of the system.

If the loss of pressure was as a result a total loss of hydraulic fluid, the system is not recoverable. An aircraft may also be fitted with a Ram Air Turbine (RAT) which is a small wind turbine that is deployed into the freestream in the event of a pump failure.

Flow Control Valves

The turbine can then be used to power a backup hydraulic pump in an emergency such as an engine failure which would otherwise cause the system to lose hydraulic pressure. A hydraulic system consists of the hydraulic fluid plus three major mechanical components.

Those components are the “pressure generator” or hydraulic pump, the hydraulically powered “motor” which powers the component concerned and the system “plumbing” which contains and channels the fluid throughout the aircraft as required. An accumulator provides a means to store fluid under pressure at different points throughout the system which can then be used to dampen pressure surges or supplement the pump under high operating loads.

Accumulators also provide limited system operation in the event of a failure of the pump. Non-pressurized reservoirs are vented to the atmosphere to allow any air trapped in the system to vent. As the level in the reservoir drops, air enters through the vent to prevent a vacuum from forming.

Pressurized reservoirs may be necessary if the aircraft operates at very high altitudes where a positive pressure in the reservoir ensures that the fluid flows into the pump at high altitudes where the ambient pressure is low.

Conservation Of Energy

On 22 June 2009, an Airbus A340-300 being operated by Finnair suffered a single tire failure during take off on a scheduled passenger flight to Helsinki and malfunction assessed as consequential by the flight crew occurred to the hydraulic system.

The flight proceeded to destination and carried out a daylight landing there in normal visibility without any further aircraft damage. Because of a further deterioration in the status of the aircraft hydraulic systems during the landing roll, the aircraft was stopped on the runway and then towed into the gate.

No persons were injured in this incident. On 18 June 1998, the crew of a Swearingen SA226 did not associate directional control difficulty and an extended take off ground run at Montreal with a malfunctioning brake unit.

Subsequent evidence of hydraulic problems prompted a decision to return but when evidence of control difficulties and fire in the left engine followed, a single engine diversion to Mirabel was flown where, just before touchdown, the left wing failed upwards.

Fire And Flash Point

All occupants were killed when the aircraft crashed and inverted. The Investigation found that overheated brakes had caused an engine nacelle fire which spread and eventually caused the wing failure. This means that if the pressure inside a hydraulic line is changed, e.g.

the pilot depresses a brake pedal, the increased pressure due to the reduced volume in the system will be transmitted equally to all points in that system. Gear pumps require some form of system protection as they will keep delivering fluid to the outlet as long as they are running, irrespective of the outlet pressure.

:max_bytes(150000):strip_icc()/crew-members-prepare-an-f-16-fighting-falcon-for-a-training-sortie--532102703-5bf485ad46e0fb00268c8d54.jpg)

It is common to install a pressure cut-off valve directly upstream of the pump to direct fluid back to the reservoir if the pressure becomes too great. A hydraulic fluid must have sufficient viscosity such that it aids in the lubrication and protection of the entire system, but not so great that it offers resistance to flow during operation.

A typical hydraulic system is made up of cylinders, pistons, valves and pumps. If the viscosity drops too low then these components will not adequately seal, resulting in leaks in the system and poor performance. This is a fire-resistant fluid which may be used in place of a mineral based fluid if care is taken to limit its use when temperatures are low.

System Plumbing Components

The viscosity of these fluids increase significantly at low temperatures compared to mineral based fluids. Always refer to your Pilot’s Operating Handbook for a list of approved fluids to be used in your aircraft. A reservoir works as a storage space in the system for hydraulic fluid.

It is important that sufficient fluid is present in the system to provide an adequate supply in all operating conditions. The fluid flows from the reservoir into the system where it performs the required actuations before returning to the reservoir.

Temperature changes can result in the fluid volume changing and so the reservoir is designed to act as an overflow during hot operation. Excess fluid is stored in the reservoir to mitigate leaks in the system which would otherwise cause the system to stop operating once a critical fluid level was reached.

To calculate the overall star rating and percentage breakdown by star, we don’t use a simple average. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon.

Pressure Control Valves

It also analyzed reviews to verify trustworthiness. On 19 July 1989, a GE CF6-6D-powered Douglas DC-10-10 at FL370 suffered a sudden explosive failure of the tail-mounted number 2 engine and a complete loss of hydraulics so that the aircraft could only be controlled by varying thrust on the remaining two engines.

With only limited flightpath control, the subsequent Sioux City emergency landing led to the destruction of the aircraft by impact and fire. The Investigation attributed the engine failure to non-identification of a fan disc fatigue crack arising from a manufacturing defect and the loss of hydraulics to debris dispersal which had exceeded the system's certification protection.

A hydraulic system operates on the principles of Pascal’s Law and the conservation of energy to transmit a force and displacement from one point to another in the system. The basic operating principles of a hydraulic system are described below.

A common accumulator used in aircraft hydraulic systems is the spherical type which consists of two spherical chambers separated by a rubber or synthetic diaphragm. The top half of the accumulator is designed to accept fluid under pressure, which reacts against air or nitrogen housed in the lower half of the accumulator.

Open Center Systems

The hydraulic pressure will compress the gas until the pressure in the two chambers is equal. When a hydraulic actuator is required to operate, the accumulator located nearest the actuator will feed fluid under pressure directly to the actuator, reducing the pressure in the accumulator which is then replenished by the system pump.

This allows for a more rapid actuation than would otherwise be possible, eliminating any lag from the mechanical pump. On 16 May 1995, an RAF BAe Nimrod on an airworthiness function flight caught fire after an electrical short circuit led indirectly to the No 4 engine starter turbine disc being liberated and breaching the No 2 fuel tank.

It was concluded by the Investigation that the leaking fuel had then been ignited by either the electrical arcing or the heat of the adjacent engine. After the fire spread rapidly, the risk of structural break up led the commander to ditch the aircraft whilst it was still controllable.

This was successful and all seven occupants were rescued. Regardless of the complexity, all hydraulic systems comprise of a reservoir to store fluid, a pump (could be a piston actuated by a foot force) to drive the system, valves to control the direction, speed and pressure of fluid flow, a filter to remove impurities, and an actuator to apply a force on the output.

Schematic Design

Flow control valves control the rate of flow and the flow direction. They can be used to operate an actuator or divert fluid away from a component. Two common flow control valves are selector valves and check valves.

hydraulic system on aircraft, 2a635 aircraft hydraulic systems, 2a635 air force, aircraft hydraulic jobs, aircraft hydraulic system components, skydrol hydraulic mule, 2a6x5, us air force cargo planes

0 Comments